Binary bits control range Period [ms] Freq. [Hz} 8 256 2133.33 0.46875 7 128 1066.67 0.9375 6 64 533.33 1.875 5 32 266.67 3.75 4 16 133.33 7.5 3 8 66.67 15 2 4 33.33 30 1 2 16.67 60 FIGURE 7. PWM switching frequency and resolution.

Because the ATmega328P master clock operates at 16 MHz and the maximum TIMER2 divisor is 1024, the minimum PWM sampling frequency is ~30 Hz, yielding four levels of resolution control. However, if we further divide the ATmega328P master clock frequency by 8, then the PWM frequency is 3.75 Hz and five-bit (32 level) resolution is achieved. Considering many practical applications, a sampling rate of ~4 Hz with five-bit resolution was an acceptable trade-off. Implementing both TIMER2 pre-scalar 1024 divisor and master clock divisor 8 is required to reach a PWM frequency of 16 MHz/(1024*256*8*2) = 3.83 Hz. Autocad 2007 portable download free. The master clock was divided in software with the clock_prescale_set(clock_div_8); function which, of course, has a similar effect on the delay(); millis() instructions. Delay values must be divided proportionally. Simio simulation crack cocaine vs. The Arduino standard PID_v1 library was also edited for the same reason and a modified PID_v1R library is included in the zip archive at the article link.

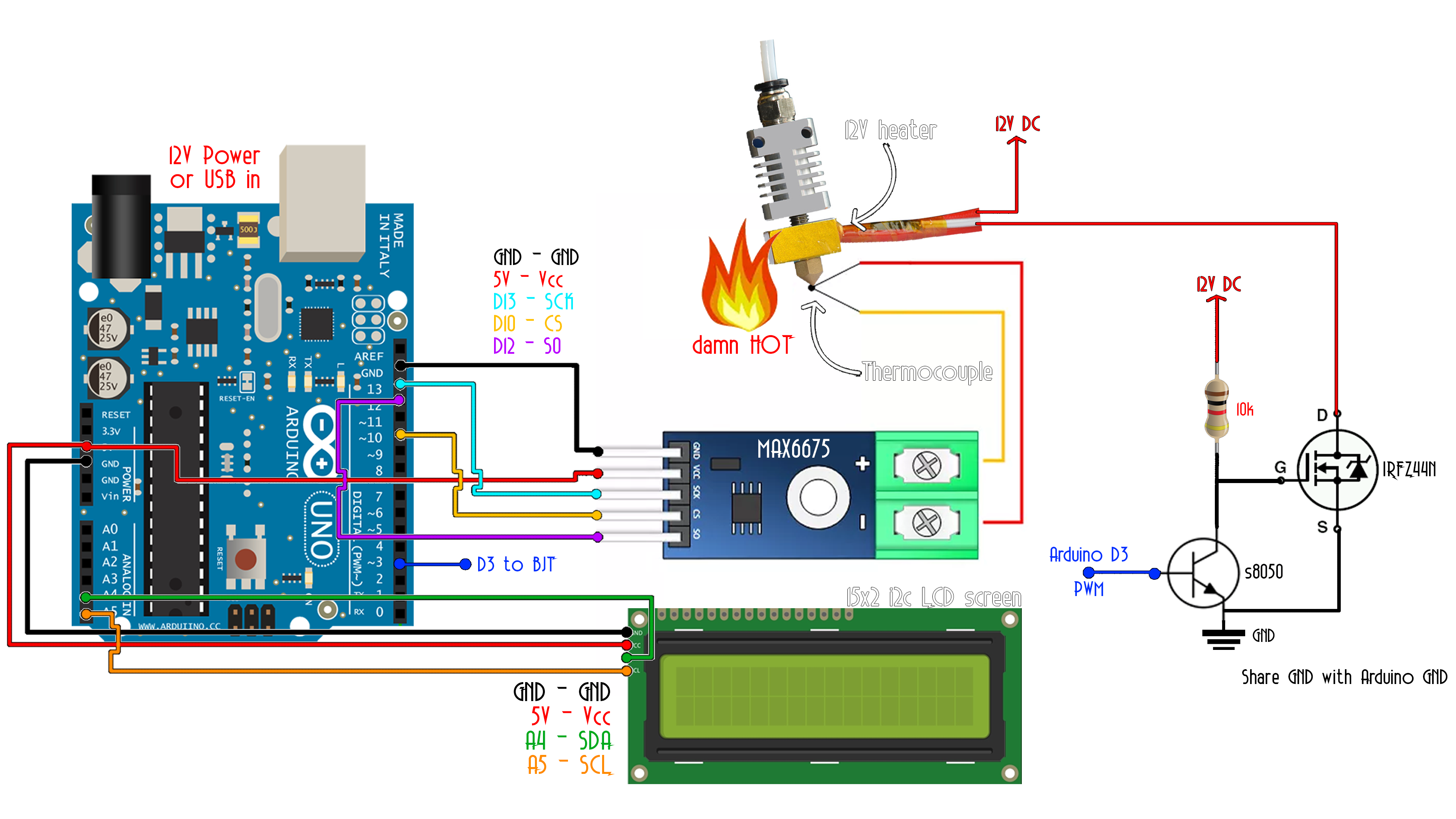

Arduino - Motor PID Speed Control. Send PID gain (kP, kI, kD) to Arduino (3) Receive motor speed -> show on graph. Visual studio program. The whole code for the Visual Studio program can be downloaded at this. Learn and make a line follower robot with PID controller in 2 hours. PID Control Line Follower Robot. Project tutorial. Apr 14, 2018 - There's also an LCD display and a FET to control the heater. The idea behind a PID controller is that you measure the difference between the current temperature and the desired temperature known as the setpoint. The proportional gain tells you how much output occurs due to that difference.

Testing To debug and validate this design, an Arduino Nano and breadboard were used with two LEDs, an SSR, and a 60W incandescent light bulb ( Figure 8). It was easy to see the LEDs flash at a slow rate (PWM cycle time) and the LED brightness change (PWM duty cycle). Arduino Nano test circuit. The definitive test was switching a 120V resistive load (60W light bulb). To my joy, flashing and variable intensity was observed.

This was the extent of bench testing before deployment. Discussion This was a satisfying project because I learned a lot about PID and made a practical PID temperature control device. The Arduino IDE and libraries made programming and testing a breeze. A few quick points: • Online cost of hardware is very cheap ($20) and can be assembled by almost anyone in just seconds. • ATmega328P microcontroller performance provides for both rapid sampling (4 Hz) and five-bit PWM SSR switching. Along with a wide temperature range (0-1024°C), this unit is ready for a variety of applications.

• Keypad selection of temperature profiles enables the user to operate stand-alone at the remote process site. • Only 30% of program memory and 60% dynamic memory are used, leaving plenty of space for user enhancements. Some practical applications might include vegetable canning, rice cooker, slow cooker, alcohol fermentation, or an SMT solder oven. Someday, I’m going to turn the PID problem around and make a device that senses meat temperature and indicates the remaining cooking time.

The Thanksgiving turkey will be cooked perfectly every time. NV Resources MAX6675 Datasheet: MAX6675 Arduino Library: All components (Arduino Uno R3, 1602 LCD keypad display, MAX6675 module and thermocouple, SSR) are easily purchased online. References • Wikipedia:.